Experience

Our Experience

Family-owned and operated for over 60 years, LAPPCO has grown from a manufacturer of simple industrial wall panels to one of the leading and most respected manufacturers of architectural precast products in the Chicagoland area.

Our dedicated team of full-time office and shop staff handles every aspect of your project, including marketing, estimating, detailing, project management, fabrication, and shipping of the precast products. We value the long-standing relationships we’ve built with the companies responsible for engineering, shipping, caulking, and erecting our panels on-site.

We have proudly serviced both the private and public sectors, integrating our precast products into various buildings across the Midwest. Our products span every spectrum of the industry, including office and industrial buildings, hospital and medical facilities, parking garages, commercial buildings, schools, financial buildings, and sports facilities.

Our production facility is a level “AA” PCI-certified plant, earning the highest attainable rating in PCI’s quality-based system. We adhere to the industry’s most stringent product and installation tolerances, attesting to the pride we have in providing the best in architectural precast products for our customers.

Our Projects

- All

- Commercial

- Educational

- Medical

- Specialty Items

College Park Office Building

In the far north suburbs of Chicago, this impressive office building blends precast techniques, using contrasting sandbuff and brick red colors with smooth acid-etched and rock-faced textures.

Conway Park Office Building

In Chicago, resilient building uses prestressed precast panels, bearing loads, enduring weather, with visual appeal. Two color mixes, acid-etched, sandblasted finishes yield cost savings for the owner.

HSBC Corporate Headquarters

Lombard Architectural Precast's skill shines in this all-precast building with three color mixes, acid-etched panels, and a rock-faced battened base, completed on time and within budget.

Toyota Park Entertainment Venue & Soccer Field

Home to the Chicago Fire Soccer team, this stadium is a versatile mixed-use structure for concerts and activities, showcasing precast in the seating, columns, beams, risers, treads, and tubs. Selected by LAPPCO for its uniqueness.

Leopardo Construction Corporate Headquarters

As a contractor, Leopardo appreciated precast panels for their HQ. LAPPCO, working with their design team, chose prestressed sandwich wall panels—cost-effective, load-bearing, and insulated. Two color mixes created a striking image. Pleased to win the contract for Leopardo's corporate headquarters.

Lincolnshire Office Center

LAPPCO, known for excellence, was chosen for a major office center with unique precast challenges: three color finishes, two mixes, 20 corners, cantilever cornices, and a Lincoln Log process. Completed on schedule and budget.

Union Tower Office Highrise

Located just west of Chicagos loop this high-rise required an escalated construction schedule. The project consisted of two color precast panels with two finishes-one acid etch and the other sand blast. Project completed on schedule.

Amcol International

Amcol International's headquarters, primarily precast, chosen after a competitive bid by LAPPCO for their lowest bid and reputation. Precast panels, prestressed for structural integrity, feature golden marble limestone.

Balmoral Office Building

This twin office building is a unique project with horizontal ribbon look, precast panels with large expanses of windows. The panels were acid-etched.

The Art Institute of Chicago Modern Wing

The Art Institute of Chicago, a renowned museum, expanded with the internationally acclaimed Renzo Piano. LAPPCO, the sole precast plant selected, crafted intricate load-bearing panels and multiple finishes, meeting precise specifications on time.

Congress Parkway

LAPPCO faced a unique challenge: crafting a custom color and finish to match a historic structure. Successfully accomplished, showcasing LAPPCO's expertise in complex building projects.

10 East Delaware – Condominiums

10 East Delaware, a 35-story luxury high-rise in Chicago's gold coast, stands at 424,836 sq. ft. LAPPCO's expertise in challenging sites played a key role in its selection. The building features diverse precast finishes, including cast stone and granite on the first floor panels.

Greenway Self Park

A notable feature of this parking garage is a 10-story precast column, housing a revolving kinetic sculpture at the building corner—a distinctive addition to Chicago's public art scene.

Laborers Union Training Center

A construction marvel, this building showcases precast concrete's benefits. Despite Chicago's harsh winter, the brick-faced panels allowed continuous construction, finishing on time and saving costs. The 51,000 sq. ft. original building and 18,000 sq. ft. addition, both completed by LAPPCO, feature a total of 491 precast panels.

Multimodal Transportation Center

Downtown Normal's unique multi-use building houses an Amtrak station, waiting areas, food court, retail, and municipal offices. LAPPCO supplied 134 precast panels for the adjoining parking structure, totaling 29,000 sq. ft. Precast seamlessly integrates with other methods, exemplifying versatile construction.

Orchard Residences

LAPPCO completed The Orchard in Lincoln Park, a key part of Lincoln Common's redevelopment. This 7-story building features 400+ precast panels with an elegant limestone-like finish. Lead by Gilbane, it marks the site's multi-phase redevelopment.

Centegra Hospital

Selected for Centegra Hospital in Huntley, LAPPCO provided 623 architectural precast wall panels. Acid-etched, custom formliner, brick clad, and insulated panels totaled 103,217 sq. ft.

Northwestern Memorial Hospital Outpatient Care Pavilion

LAPPCO supplied 388 precast panels for Northwestern Memorial HealthCare's new Outpatient Care Pavilion in Streeterville, spanning 54,600 sq. ft. The 25-story structure includes 14 medical floors, 2 public and retail floors, 2 mechanical floors, and 7 parking floors, meeting LEED standards for sustainability.

Children’s Memorial Hospital

LAPPCO's Children’s Memorial Hospital project used 1,724 panels, with 75% using efficient steel molds. The transformed hospital, now Ann & Robert H. Lurie Children’s Hospital, spans 1.25 million sq. ft., with 313 beds, marking a significant growth in pediatric care. LAPPCO takes pride in contributing to this transformative expansion.

Takeda Pharmaceutical Headquarters

A precast challenge for LAPPCO's mixologist involved matching exposed granite aggregate panels to genuine stone. After several test batches, an exact match showcased concrete precast panels' versatility.

Hospira Pharmaceutical Headquarters

This major project incorporated several precast panel applications. One of the most interesting uses of precast was acid-etched “grillage shaped”(looks like the front grill of a car) prestressed panels at the roof used to hide the extensive mechanical equipment.

Melvin and Bren Simon Cancer Center

A $5M precast contract for Clarian Health-Indiana University's cancer center featured 900+ panels in a 94,000 sq. ft. building. LAPPCO's unique technique embedded Indiana limestone into precast panels, closely resembling on-site construction with considerable time and cost savings. Their experience and competitive bidding secured this major contract.

Edward Hospital Parking

The massive five-story parking structure, completed in record time, incorporated architectural load-bearing spandrels and columns with acid-etched and sandblasted finishes. Erection was coordinated with a structural producer supplying double tees and stair towers.

Provena Medical Center

The new bed tower structure called for brick clad panels to exacting specifications. LAPPCO also met the challenge of a very escalated construction schedule.

Delta Dental Building

Delta Dental chose LAPPCO for their reputation. The building demanded various precast panel finishes, including larger utility brick clad panels, acid etch, sandblast, and custom rock face panels.

Silver Cross – Medical Office Building

Here LAPPCO had to produce two interesting finishes. One a faux granite finish, which is considerably less expensive than real granite while achieving the granite look. The other at the base of the building, a unique river pebble finish.

Little Company of Mary – New Bed Tower

This new bed tower replaces the old building adjacent to this building. LAPPCO was selected based on their extensive medical experience and capacity to produce over 600 panels with three brick clad finishes on a very tight schedule.

Riverside Medical Center Addition

Riverside is a major medical facility for Kankakee County. The project required three different color mixes that needed to be formulated to very exacting specifications. The work was completed ahead of schedule to the complete satisfaction of the client.

University of Chicago – Comprehensive Cancer Center Silver Cross Hospital

LAPPCO's medical expertise secured the bid for this project, following the completion of a nearby medical office building. The 15,700 sq. ft. attractive structure featured various precast finishes, including rock face and acid-etched panels in multiple colors. Comprising 76 panels, the project was successfully completed on time and within budget.

University Center

LAPPCO played a vital role in Chicago's $150 million University Center, the largest joint residence hall in the U.S. Catering to 1,700 students from Columbia College, DePaul University, and Roosevelt University, LAPPCO created and installed 1,400 custom-designed precast panels within a strict timetable. Completing the 18-story, 702,000 sq. ft. building in two years was a priority, influencing the construction manager's choice of LAPPCO for the project team.

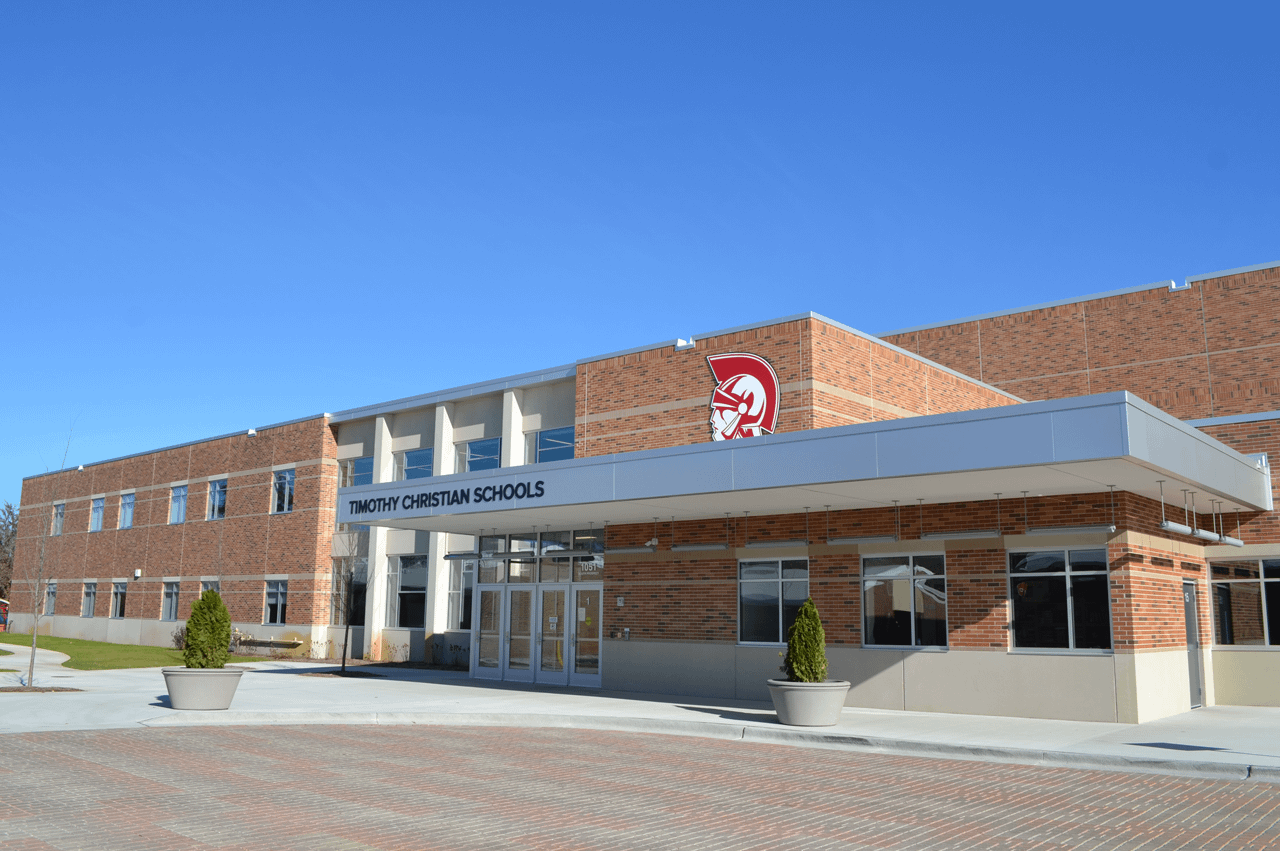

Spencer Pointe Grammar School

Ideal for schools, prestressed sandwich wall panels encapsulate insulation, offering excellent R-values and efficient installation. The tough finished interior eliminates the need for costly finishing, while the acid-etched exterior provides an attractive look.

Marian Catholic High School – Leadership Center

The high school addition features striking prestressed, insulated, acid-etched load-bearing panels with circular windows, showcasing the benefits of sandwich wall construction—solid, quick installation, and pre-finished tough interior walls.

Robert Morris addition to the Culinary College

This project utilized all precast prestressed, load-bearing, acid-etched panels, highlighting the significant cost-effectiveness and time savings of precast concrete. The accelerated schedule had all panels erected within a week, further minimizing time and labor costs.

Colin Powell Middle School

An excellent example of precast construction's cost savings, LAPPCO was chosen for a budget-conscious school project. The all-precast panels were finished on-site with a painted finish.

Storm Shelter Projects

Many school designs include storm shelter areas, often utilizing precast wall panels. LAPPCO completed projects with storm shelters for Elmhurst SD 205, North Shore SD 112, Echo Joint Agreement, Plainfield SD 202, and Lansing SD 158.

St. Daniel Parish Gymnasium

Gymnasiums benefit from sandwich wall prestressed load-bearing panels, providing a large open central area. This application features tough, pre-finished interior walls, reducing costly finish work. The acid-etched exterior with a rock-faced look at the base adds aesthetic appeal.

Little Company of Mary – Medical Office Building

This project is a great example of recent contract awards by clients who appreciate LAPPCO’s quality and price advantage. The building is 19,000 sq. ft. consisting of 165 panels.

Beltone Corporate Headquarters

Beltones Architects used sandwich wall precast panels for an economical, attractive two-story building. Prestressed and load-bearing, they support the roof and second floor, incorporating insulation and featuring acid-etched, sandblasted, and simulated granite finishes.

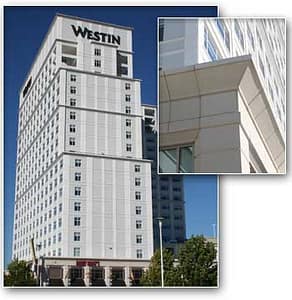

Westin North Shore Hotel

Challenging project with two-story precast panels, 15' wide, requiring pre-stressing. Load-bearing, acid-etched, and sandblasted finishes served various functions, while the high-rise used poured-in-place concrete.

Westin Hotel Yorktown Plaza

As a compliment to LAPPCO’s excellence, this is the second project by Westin hotel group. Precast portion: two-story, two-color, acid-etched, brick-clad, load-bearing panels for restaurant and meeting rooms at the hotel's base.

Orchard Residences

December 7, 2023

No Comments

LAPPCO completed The Orchard in Lincoln Park, a key part of Lincoln Common's redevelopment. This 7-story building features 400+ precast panels with an elegant limestone-like ...

Read More →

College Park Office Building

December 8, 2023

No Comments

In the far north suburbs of Chicago, this impressive office building blends precast techniques, using contrasting sandbuff and brick red colors with smooth acid-etched and ...

Read More →

Conway Park Office Building

January 18, 2024

No Comments

In Chicago, resilient building uses prestressed precast panels, bearing loads, enduring weather, with visual appeal. Two color mixes, acid-etched, sandblasted finishes yield cost savings for ...

Read More →

Westin North Shore Hotel

January 18, 2024

No Comments

Challenging project with two-story precast panels, 15' wide, requiring pre-stressing. Load-bearing, acid-etched, and sandblasted finishes served various functions, while the high-rise used poured-in-place concrete.

Read More →

Westin Hotel Yorktown Plaza

January 18, 2024

No Comments

As a compliment to LAPPCO’s excellence, this is the second project by Westin hotel group. Precast portion: two-story, two-color, acid-etched, brick-clad, load-bearing panels for restaurant ...

Read More →

HSBC Corporate Headquarters

January 18, 2024

No Comments

Lombard Architectural Precast's skill shines in this all-precast building with three color mixes, acid-etched panels, and a rock-faced battened base, completed on time and within ...

Read More →